Services.A wide range of Electrical Engineering and Control Systems Engineering services are available.

|

Factory AutomationFactories can contain complex automated machines and integrated lines. Sometimes these machines can be

- replaced with OEM equipment or, - upgraded using existing equipment or, - the in-house design of new equipment. If you have a pinch point in production, automation can remove line delays and increase throughput. AIA has worked in hundreds of factories in SE and Country Qld, to design, repair and maintain equipment... from small pencil screen printing machines to heavy industry, from one of the largest steel producers to major facilities such as soft drink manufacturers and bottling plants. |

Agricultural AutomationPacking and processing sheds have machinery for storing, conveying, weighing, grading, sorting, packing, washing and handling of produce. Some processes are manually controlled, and others automated. AIA has worked with packing shed equipment manufacturers to design, build, install and maintain equipment such as conveyors, punnet wrapping machines, camera graders, labelling machines (even no contact labelling for delicate fruit), packing monitoring systems. Also prototyping of macadamia high speed nut cracking machines with automated kernel and shell separation.

|

Emergency Power and UPSA decade in alternative power systems and telecommunication power systems, AIA gained extensive experience in solar, UPS, diesel generation, wind turbines, hybrid systems and batteries. Designing systems from a few hundred watts, to commissioning multi-megawatt systems for Telstra. We have worked on power systems for large Telstra exchanges, contracted by Q-Build and Schneider for UPS servicing. UPS and generator system designs for all government high rise buildings in Brisbane, down to servicing small UPS systems in Eye Surgeries for operating theatre power validation.

|

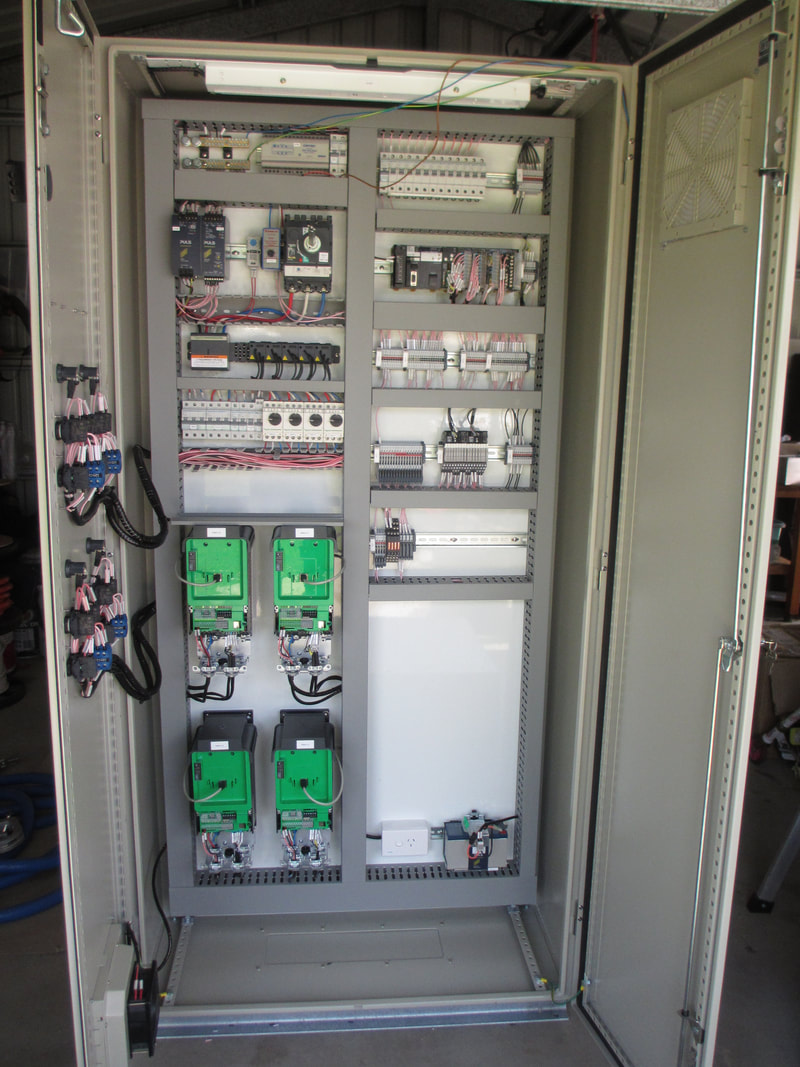

Control SystemsControl Systems Engineering covers all the field areas of automation, SCADA, telemetry, drives and instrumentation. A whole control system is generally a network of connected devices, from/to the field instruments and actuators (VSD, hydraulics, pneumatics), into controllers (PLCs & RTUs) and then data is pushed through communications transport using radio/microwave/fibre/bus networks and displayed on HMI panels or SCADA screens on computer. AIA has worked in private industry as system integrators, local government, upgrading, servicing controls and telemetry for water and waste-water treatment plants, pump stations and monitoring stations. For example, AIA as part of the project team, upgraded the entire Unity Water controls network. Also on the team that upgraded Capalaba Water Treatment Plant's sitewide control system.

|

Factory Project EngineeringFactory project engineering involves not only the automation but also the structure and factory layout to contain this equipment. For instance, working in Projects Engineering for a large food processing plant. The factory upgrades and refurbishments required the co-ordination of multiple trades from all areas and factory services crossing over each other in difficult spaces. Each major factory change requires a lot of planning, budgeting and purchasing. For example, we inserted an in-line lab into two floors containing process equipment, ducting and pipes etc.. surrounded by a 24/7 food grade processing area during and after shutdown maintenance periods involving many services and trades. CAD modelling, as a tool, was instrumental in preventing any clash of services and providing each trade a clear picture of their tasks.

|

AutoCADCAD

- provide 2D drawings for electrical, structural and process P&ID schematics. - provide 3D drawings with various renderings of equipment, switchboards, structural or layouts for any system or building. - provide walk through virtual models or produce an animated presentation of a walk through or fly around of any model created. -building anything in virtual space before construction such as factory or packing shed layouts. - Local site visits for drawing or specification markup sessions. The advantages of CAD as a tool are limitless, while also providing the opportunity for Building Information Modelling and Digital Twins. The ability to go from virtual-to-real without mistakes. |